The beginning of 2018 was a busy time for the workshop here at S and A Engineering Services Ltd. Repairing blowers is our core business and speciality, successfully overhauling many different manufacturer’s machines and doing our utmost to meet the time constraints our customers require.

Occasionally there will be a phone call made with urgency regarding a blower failure on site which would cause a production line to cease, costing the factory thousands in lost revenue. February saw one of these phone calls from a flour miller in the North East of England. Both their duty and standby machines had failed and was threatening to shut down production.

The machine would take too long to repair and return; it was simply not an option. Using our 30+ years’ experience in this sector, we quickly assessed whether we had a refurbished machine on our shelf that would handle the workload required. A direct replacement was not available so we sought the ‘best fit’ solution that was ready on our shelf.

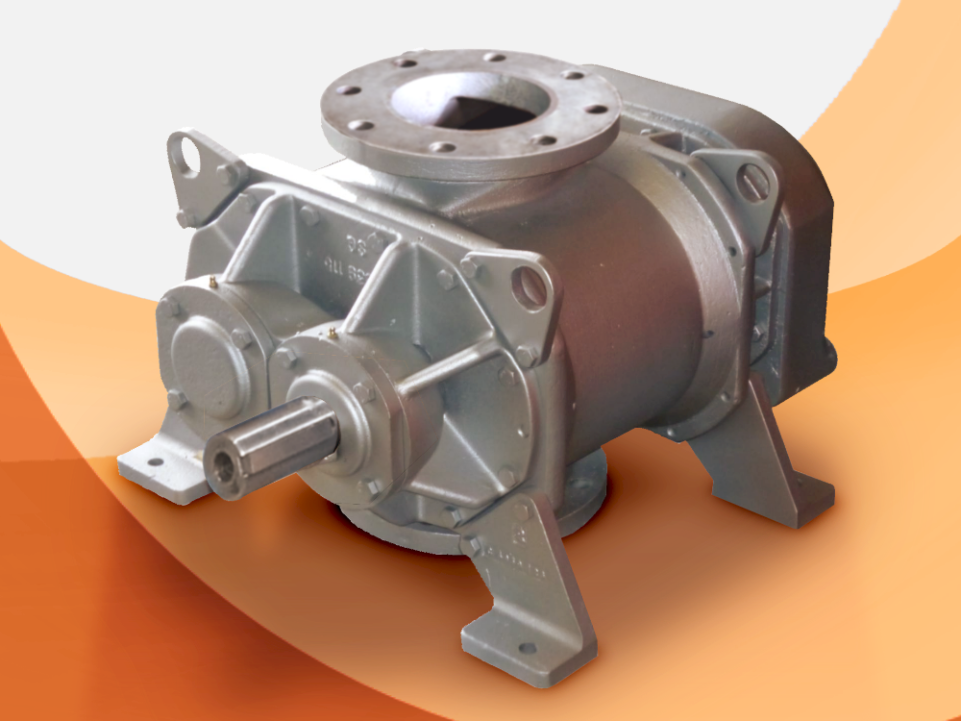

Customer blower had snapped shaft, damaged gears and a list of other damaged parts

Customer blower had snapped shaft, damaged gears and a list of other damaged parts

Demonstrative photo

An alternative blower was taken to site to enable them to keep their production running whilst their blowers were repaired.

The substitute blower was loaded on to our service engineer’s van who set off the same day directly to our customer’s factory over 100 miles away, assisting with the minor alterations required on site to retrofit the refurbished machine. The initial plan was to hire this refurbished unit until their blower could be overhauled.

The engineer returned to the workshop with the customer’s damaged blowers for assessment. Although one of the machines was repairable, the other was found to be beyond economical repair as major parts including the drive shaft were found to be broken. Determined to provide a full, cost effective solution for our customer, we located a refurbished unit of the same model and size from Europe as an alternative for purchasing a costly, new machine. The customer was happy with the offer, and both the refurbished and in-house repaired machines were returned back to site.

Needless to say, our customer was very happy that a potential disaster had been averted. If we can, we will always help a customer in need, give us a call to see what we can do to help.