We received an enquiry from a repeat customer who operates worldwide.

Their new enquiry revolved around an installation based in Japan with an old Hick Hargreaves package unit and had requested parts to repair their blower.

The parts they requested included impellers; which are one of the major components of a blower, unfortunately these are no longer available for Hick Hargreaves machines. Options were discussed including them sending the blower to us from Japan for repair, supplying a new complete packaged are blower, or supplying a new blower to retrofit in its place.

The required timeframe was too short to risk sending the blower for repair.

And given that the blower room was built around the existing Hick Hargreaves blower package; it would not be possible to bring in a new replacement package, leaving us the option to replace the bare-shaft blower only

A lot of information travelled back and forth, including images, dimensions of the current installation, space and installation restrictions, all the while trying to identify and resolve potential problems they may encounter for each option.

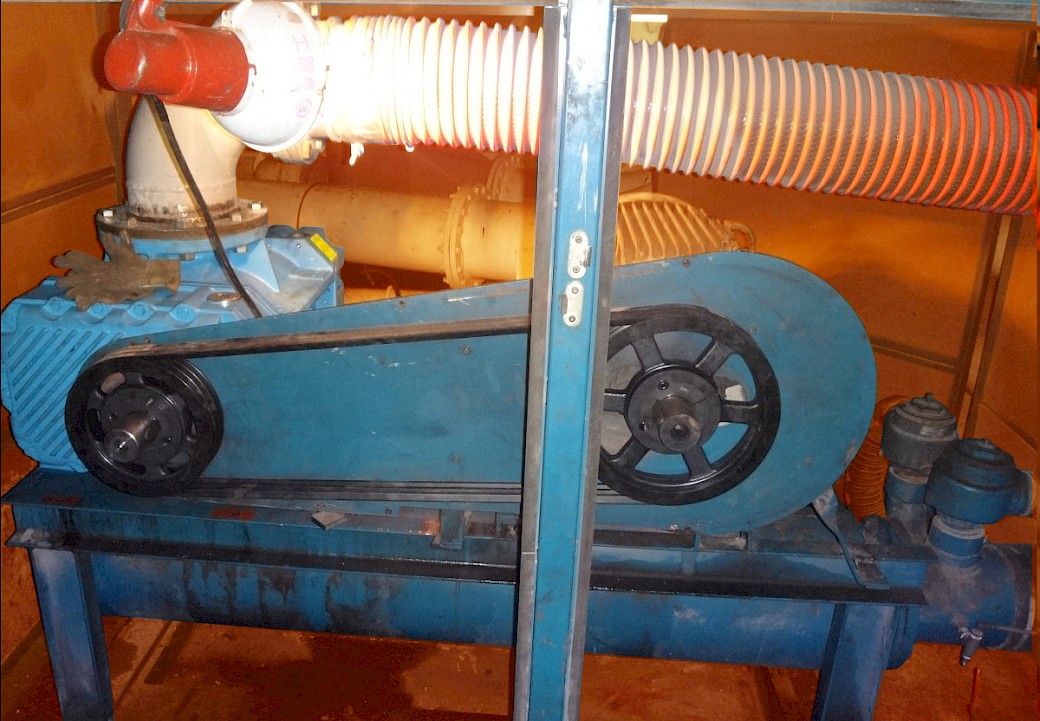

Customer photo of original Hick Hargreaves Package

Ancillary parts labelled up

Customer photo of package after installation

As there is no current range blower which directly fits in place of the Hick Hargreaves 4000 or 4200 range of blowers in every way, it becomes a search for the ‘best fit’ solution which can handle the airflow, system pressure and dimensional constrictions.

Once we had identified the best fit solution and the customer was happy with the suggestion, price and lead-time, we proceeded with the order.

Part of the order included a step-by-step instructional guide detailing the modifications required to their current setup to enable the new blower to be fitted in its place. This included instructions the modification of the drive guard, base frame mounting hole locations and length of the adjoining pipework.

The new blower was supplied along with new gaskets, a new drive arrangement including blower pulley & taper lock bush, motor pulley and taper-lock bush and drive belts so that the new blower would run at the correct speed to achieve the necessary airflow and finally a full set of new fixing bolts, washers and nuts.

The hard work and preparation paid off; the blower was successfully installed with the instructed modifications and the customer was very satisfied with the preparatory guidance, demonstrating that with enough information the will and a way; obsolete blowers can be replaced, even in awkward circumstances.